Meet Solera

We work every day to consolidate our position in the industry

Choose an article

Experience, quality and innovation

Solera sets the standard as one of Spain’s largest manufacturers of low voltage electrical equipment. With more than 50 years of experience in the industry, Solera manufactures, designs and markets more than 2,000 products, offering its distributors a full range of solutions for electrical installations.

Its two factories, located in Cañete (Cuenca) and Paterna (Valencia), are equipped with the most innovative technologies, making it possible to achieve a high production and service capacity, both domestically and in the more than 38 countries to which it exports.

Any expansion comes with new commitments. Year after year, new goals are set related to quality and social responsibility policies, prioritising the health and safety of our employees and making clear commitments to the environment.

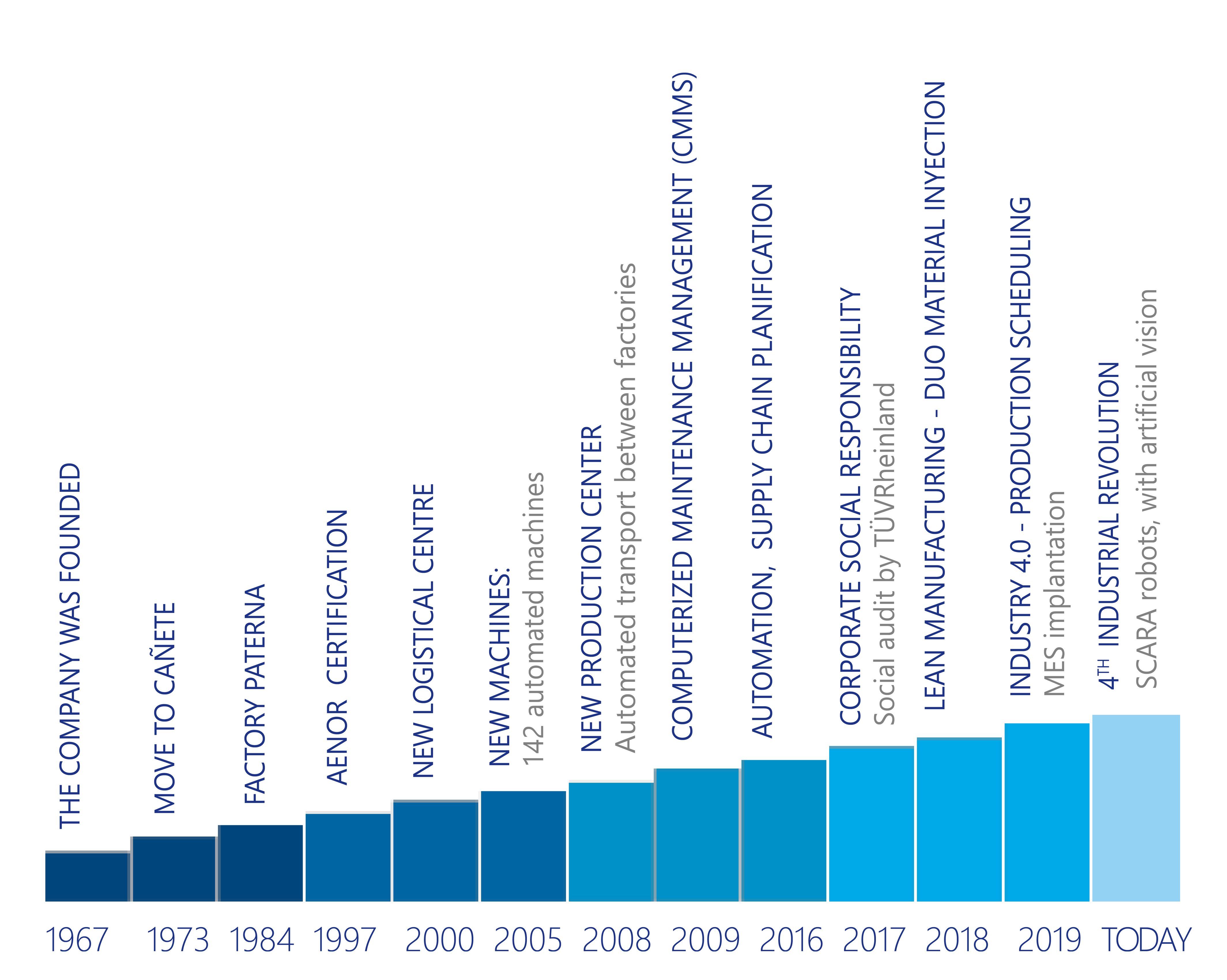

Learn about our history and more than 50 years of experience

From a small workshop in Hospitalet, to the implementation of Industry 4.0... Click here to learn about our history.

Industry 4.0

Data, technology and digitalization for process improvement and sustainability.

In a demanding and competitive environment, Solera is committed to technology and the digitisation of its processes. As shown, the recent implementation of Industry 4.0 —including the application of tools focused on transforming and digitising business models and operations— has one objective: value generation.

Transforming Solera’s production centres into smart factories, where established indicators can be monitored in real-time, makes it possible to achieve significant improvements in decision-making and its results.

More than 142 automatic machines equipped with PLCs (Programmable Logic Controllers), monitors and touch screens connected to the MES. (Manufacturing Execution System), production sequencing tools and comprehensive maintenance management allow for high production capacity and a quick and flexible response.

Solera's industrial evolution

LEAN Philosophy

Lean is a methodology created by Toyota. Its focus is on continuous improvement and customer value, paving the way for improvements in productivity, competitiveness, and provided service.

The Lean Management methodology has been implemented in Solera’s production plants and logistics centre. Its quality and sales departments have also implemented the Lean Management project management system.

For Solera, the foundations of this system are based on standardised, stable and reliable processes. Its principles include:

Production Capacity

Following the most advanced approaches to production management, Solera manufactures its products using optimised processes and the most effective and competitive human and material resources.

The company has more than 20,000 m2 of production space between its two factories, making it possible to meet the supply needs of its customers.

injection machines

automatic machines

workstations

parts manufactured per day

Logistics

Supply chain and logistics process management is characterised by its flexibility and effectiveness, making it possible to meet customer requirements within an increasingly demanding environment, both domestically and internationally.

with real-time radio inventory control

order lines shipped each day

pallets of storage capacity

shipments made each year

Mission

Solera’s mission is to supply low-voltage electrical equipment to the domestic and international market, with minimal environmental impact, obtaining the profitability necessary to make it financially viable and focused on exceeding the expectations of all parties involved, including our customers, suppliers, management, employees and the company as a whole.

Vision

A company with an excellent human team that empathises with all parties involved, offering excellent service and outstanding value for the money.

Values

Respect for the environment

Strength

Social responsibility

Commitment

Sustainability

Balance

Future-focused

R&D

Communication

Transparency

Honesty

Continuous improvement

Ethics

Efficiency

Team spirit

Creativity

Generosity

Consistency

AENOR is a non-profit organisation.

Since 1989, has been responsible for standardisation in Spain, as well as the certification of products according to the corresponding implementing rules. In 2017, it split into two entities:

UNE Spanish Association for Standardisation

AENOR Spanish Commercial Certification Association.

AFME is a non-profit professional organisation operating nationally and covering the various sub-sectors of the electrical industry.

Its mission is to defend the leading position of electrical equipment manufacturers in matters like standardisation, legislation and certification, to support their national market and increase exports through their services.

COFME is a consortium of electrical equipment manufacturers.

Whose mission is to satisfy the needs of the most demanding users and provide cutting-edge solutions in projects throughout the world. All this in compliance with the strictest international standards.

COFME’s members include CELO, DAISALUX, FERMAX, SACI, SALICRU, SODECA, SOFAMEL and SOLERA. Top-ranked domestic manufacturers with a clear customer orientation.

AIMPLAS is a Technology Centre with 30 years of experience in the plastic sector.

It provides solutions to companies throughout the value chain, from raw materials manufacturers to processors and end users.

Its mission is to add value for companies so that they can create wealth and generate jobs. Through R&D, it helps solve the challenges facing society in relation to plastics, to improve people’s quality of life and ensure environmental sustainability.

AMBIAFME is a trademark of AMBILAMP.

Produced by the collaborative agreement with the Association of Electrical Equipment Manufacturers (AFME) to service electrical equipment producers, as desired and affected by the WEEE RD 110/2015.

Its mission is to help electrical professionals to recycle their professional Waste Electrical and Electronic Equipment (WEEE).

A non-profit organisation that cares for the environment through the recycling and eco-design of packaging in Spain.

Its mission is to provide society with a collective response from economic agents to environmental issues related to the consumption of household packaging products, achieving compliance with the objectives established by law, with the greatest efficiency in the use of the company’s resources.